The activated sludge process is a conventional biological process that is used for reduction of organic matter present in the wastewater. It basically involves the oxidation of carbonaceous biological matter, for reduction of the organic pollutants. The process takes advantage of aerobic micro-organisms that can digest organic matter in wastewater, and are then wasted as sludge, thereby removing the non-active microbes from the system. The supernatant from this process can be further clarified in a secondary clarifier, thus providing an effective reduction of pollutant parameters.

This basic process can also be coupled with Anaerobic / anoxic process for reduction of nitrogenous matter or phosphate. Part of the settled material, the sludge, is returned to the aeration system to maintain the active microbial mass for degradation of the incoming wastewater entering the tank.

Advantages of activated sludge process:

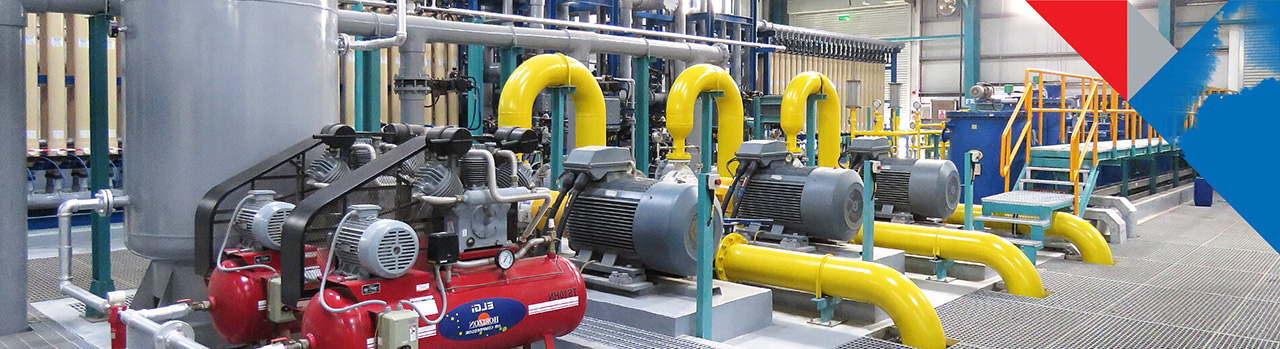

We have installed more than 70 high efficiency aerobic activated sludge systems. These systems incorporate fine bubble diffusers for aeration and most are designed with a removable headers concept. All of our systems have been able to produce treated water with very low organic pollutant (BOD, COD, etc.) concentrations, well within what is required to meet the client’s discharge specifications. Many of these installations have been designed as extended aeration systems.

Extended aeration is a type of activated sludge process with long aerobic detention time to generate overall less excess sludge and no primary settling. These systems are designed for a low F:M ratio (0.1 kg BOD/kg MLSS-day) and a high SRT (20 – 30 days). Extended aeration process has many benefits, including easy operation, better at handling organic loading and flow fluctuations, odour free systems and relatively low sludge yield.

These systems have been successfully installed by us for various municipalities and industries such as distilleries, breweries, yeast, pharmaceuticals, textiles, soft drinks, food, petrochemicals, chemicals, paper, etc.